LASER CUTTING HEAVY GAUGE

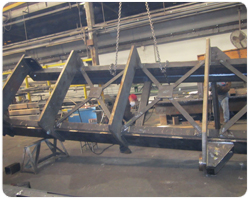

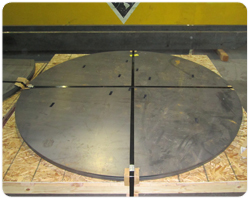

A customer, who produces air compressors, approached Chicago Metal Fabricators to laser cut 5 machinery base frames. Utilizing a 8 kW fiber laser, we laser cut the 1/4″ thick A36 steel machinery base frames while holding tightest tolerances of +/- 1/32″ throughout production. Following cutting, the frames were welded, machined and put through a CNC 350 ton press brake. Each of the 8,500 lbs frames was finished with a powder coat (semi-gloss black) and met ISO 9001-2008 specifications.

Learn More